Weathering steel, often referred to by the genericized trademark COR-TEN steel and sometimes written without the hyphen as corten steel, is a group of steel alloys that were developed to eliminate the need for painting and form a stable rust-like appearance after several years’ exposure to weather.

The surface oxidation of weathering steel takes six months, but surface treatments can accelerate the oxidation of corten steel to as little as one hour.

Weathering steel grade chemical composition (excl. iron) by weight (%)

| Grade | C | Si | Mn | P | S | Cr | Cu | V | Ni |

|---|---|---|---|---|---|---|---|---|---|

| ASTM A242 | 0.12 | 0.25–0.75 | 0.20–0.50 | 0.01–0.20 | 0.030 | 0.50–1.25 | 0.25–0.55 | 0.65 | |

| ASTM A588 | 0.16 | 0.30–0.50 | 0.80–1.25 | 0.030 | 0.030 | 0.40–0.65 | 0.25–0.40 | 0.02–0.10 | 0.40 |

ASTM A242 is available in Type 1 and Type 2. Both have different applications based on the thickness. Type 1 is often used in housing structures, the construction industry, and freight cars. Type 2 steel, which is also called Corten B, is used primarily in urban furnishing, passenger ships, or cranes.

| Grades | Width | Length | Thickness |

|---|---|---|---|

| Corten A | Up to 3000mm | Up to 12000mm | From 2mm |

| Corten B | Up to 3000mm | Up to 12000mm | From 2mm |

A588 is available in steel plate and starts at 3/16” thickness and increases up to 5” thickness. A588 is a high strength low alloy plate used for structural applications such as buildings and bridges.

Weathering steel’s benefits

Weathering steel offers several advantages that make it a popular choice in construction and architectural applications. Here are the key benefits:

- Enhanced Durability: Corten steel forms a stable rust-like appearance after exposure to weather, which acts as a protective layer preventing further corrosion. This makes it highly durable in harsh weather conditions.

- Low Maintenance: The protective layer that formscorten steel reduces the need for painting and maintenance, lowering long-term costs and efforts compared to conventional steel.

- Aesthetic Appeal: The unique rust-like appearance of corten steel is often considered aesthetically pleasing and is used for architectural purposes to achieve a rustic or industrial look.

- Eco-Friendly: The longevity and reduced need for protective coatings make weathering steel an environmentally friendly option, as it reduces the use of volatile organic compounds (VOCs) found in paints and coatings.

- High Strength: Weathering steel retains high tensile strength, making it suitable for structural applications where strength is critical.

- Versatility: It can be used in a variety of applications including bridges, buildings, railcars, and outdoor sculptures.

- Resistance to Atmospheric Corrosion: Weathering steel is particularly resistant to atmospheric corrosion compared to other types of steel, which makes it ideal for outdoor use in various environments.

Weathering steel’s disadvantages

Weathering steel has its pros and cons. Let’s take a look at its disadvantages.

- Using weathering steel in construction presents several challenges. Ensuring that weld points weather at the same rate as the other materials may require special welding techniques or materials.

- Weathering steel is not rust-proof in itself: if water is allowed to accumulate on the surface of the steel, it will experience a higher corrosion rate, so provision for drainage must be made.

- Weathering steel is sensitive to humid subtropical climates, and in such environments, it is possible that the protective patina may not stabilize but instead continue to corrode.

- The rate at which some weathering steels form the desired patina varies strongly with the presence of atmospheric pollutants that catalyze corrosion.

What are the main components of Corten Steel, and how do these components affect its weathering properties?

As mentioned above, the main components of Corten Steel, also known as weathering steel or COR-TEN Steel, are iron along with added alloys such as copper, chromium, nickel, and phosphorus. These components significantly affect its weathering properties in the following ways:

Formation of protective rust layer: The combination of copper, chromium and nickel promotes the formation of a stable protective rust layer on the surface of weathering steel. This layer acts as a barrier, slowing the penetration of moisture and oxygen into the underlying steel.

Improves corrosion resistance: The presence of chromium and copper significantly improves the corrosion resistance of steel. The protective layer of rust that forms on the surface is more durable and more resistant to peeling or peeling than the rust that forms on traditional steel.

Slows the rate of corrosion: The alloys added to weathering steel slow the overall rate of corrosion, making it more suitable for outdoor applications where exposure to the elements is unavoidable.

Reduced maintenance costs: Due to improved corrosion resistance and the formation of a self-healing protective layer, weathering steel requires almost no maintenance, saving costs over its lifetime.

What are the advantages of Corten Steel in building and landscape design compared to ordinary steel?

Corten steel can naturally form a protective layer and can be used without painting. It has unique color and texture changes and has strong artistic expression. It is easy to construct and maintain, and has low maintenance costs. Therefore, compared with other steels, it is widely used in architecture and landscape design:

Building facades: Corten Steel can be used for the exterior walls, roofs and other parts of buildings, adding unique visual effects and durability to the buildings.

Landscape sculptures: In landscape design, Corten Steel is often used to make sculptures, landscape walls and other artworks, showing its unique artistic charm and cultural connotations.

Bridges and roads: Due to its excellent weather resistance and beautiful appearance, Corten Steel is also widely used in the construction of infrastructure such as bridges and roads.

How do we ensure the structural safety and durability of Corten Steel during design and manufacturing?

During the design and manufacturing process, ensuring the structural safety and durability of Corten Steel (weathering steel) is a comprehensive task involving multiple links such as material selection, structural design, processing and manufacturing.

1. Material selection and quality control

We purchase materials from a number of reliable suppliers to ensure that the selected corten steel meets relevant national or international standards, and conduct strict quality inspections on the materials, such as material strength, toughness, weather resistance, chemical composition analysis, mechanical properties testing, etc.

2. Reasonable structural design

Our company has a number of professional designers who can carry out reasonable structural design according to the use environment and load requirements to ensure the strength and stability of the structure, set up drainage systems based on the weather and product usage, etc. Carefully design details such as connection parts and welding joints to ensure that the overall performance of the structure is not affected.

3. Precision processing and manufacturing

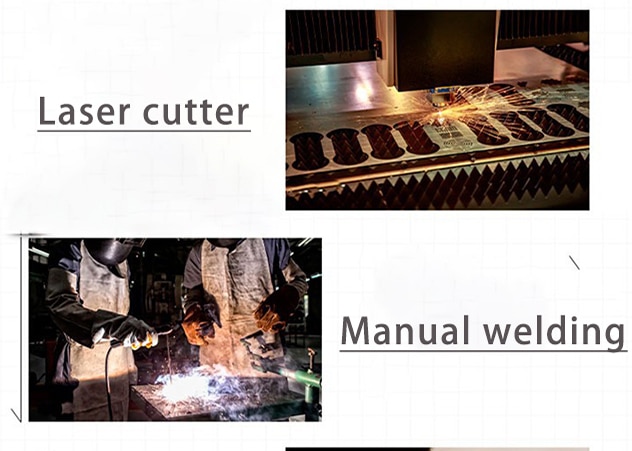

Adopt advanced processing equipment and processes to ensure processing accuracy and surface quality. Strictly control the welding process, including the selection of welding materials, the setting of welding parameters, the processing of welding joints, etc., to ensure welding quality.

Kewei focuses on the field of steel structure engineering, especially the application of Corten Steel, and strictly abides by the above principles to ensure the safety and durability of the structure. In addition, the company will continue to improve product quality and performance through technological innovation, process optimization, and management level improvement. Please contact us for more details

Specific data or estimates of the service life of Corten Steel

There is no fixed and specific data on the service life of Corten Steel (weathering steel), because it is affected by many factors, including environmental conditions (such as climate, humidity, pollution level, etc.), load conditions, design quality, and construction quality. and subsequent maintenance, etc. Generally speaking, Corten Steel can have a longer service life than ordinary steel in ordinary environments due to its unique weather resistance. However, the specific service life needs to be evaluated and predicted on a case-by-case basis.

In the Central Plains of China, where the air humidity is low, a bbq grill in corten steel can be used for more than five years or even longer.

Some studies have shown that under appropriate environmental conditions, the rust layer on the surface of Corten Steel can form an effective protective layer, thereby greatly extending the service life of the steel. However, if the environmental conditions are harsh, such as high humidity, high pollution, etc., or the steel is physically damaged, such as scratches, impacts, etc., it may shorten its service life.

Differences and precautions in welding and cutting processes of Corten Steel and ordinary steel

Corten Steel welding requires the use of welding materials that match its chemical composition and mechanical properties. The selection of welding materials should meet or exceed the performance requirements of the parent material. During the welding process, welding parameters such as welding current, voltage, welding speed, etc. need to be controlled more accurately. After welding, the weld joint needs to be treated as necessary, such as removing welding slag and grinding.

Corten Steel can be cut by flame cutting, plasma cutting, laser cutting and other methods. When choosing a cutting method, consider factors such as cutting accuracy, cutting speed, and cost. Relevant parameters such as cutting speed, gas flow, and cutting power also need to be controlled during the cutting process. After cutting, the cut surface needs to be treated as necessary, such as removing burrs and grinding, to improve the appearance and performance of the cut surface.

Precautions

During the welding and cutting process, care should be taken to prevent overheating and oxidation of the cutting heat affected zone (HAZ) to avoid affecting the performance of the parent material. The weld joint should try to avoid defects such as cracks and slag inclusions. The flatness and accuracy of the cut surface should be ensured during cutting.